1kz-te Cylinder Head Crack

As many of you will know, I use my 1998 KZJ95 UK-spec Colorado for towing a double horse trailer. When I bought it, I expected the 3.0 litre 1KZ-TE turbo diesel to be well up to the job of pulling around two tons with four or five occupants plus equipment. The reality has been different and I have suffered constant coolant loss when towing – when the reservoir overflows – and also suffered a cracked cylinder head in 2010. I should say that I don’t hammer the car at all and always try to keep it spinning on as light a throttle as possible when towing.

Mar 3, 2015 - If you are you're likely to be a victim of the dreaded cracked cylinder head. This article will walk you through the simple steps you will need to. Hi guys I have a 03' hilux with a 1KZ-TE engine and need to fix a cracked head on the old girl. Does anyone know of a good place to get a recon head or even a new one?

When I replaced the cylinder head (with a ‘Roughtrax’ unit), I hoped all would be well, but the coolant loss persisted when towing. When running without a trailer it seemed fine, usually. A couple of weeks back my wife and I were going to collect horse bedding and feed using the empty horse trailer. Travelling along the M9 at normal legal speeds (for trailers) everything was fine and I turned the cabin heater off. A couple of miles further on I suddenly realised that the temp gauge was ‘off the scale’ so pulled off the motorway and parked-up.

The engine bay was soaked in red coolant and the reservoir was bubbling like a kettle. I turned the motor off and let it cool for 10 mins or so before cautiously removing the radiator cap (heavy gloves and a towel were deployed and a lot more bubbling ensued).

I put about 4 litres of red coolant in, started it up and continued, using back roads. All was well (though I did have the cabin heater on this time). When I eventually got home with the empty trailer, having made the delivery to the Livery Yard, I checked under the bonnet. The top of the radiator was too hot to touch, but the bottom radiator hose was cold. Two possibilities came to mind: 1.

The thermostat I acquired from Milners in 2010 wasn’t working (though I did check it before fitting it). The head gasket was letting combustion pressure into the water channels which was then ejecting the coolant. I discounted a cracked head as there was no sign of steam when re-starting from hot. So, as the Queen of Hearts would say.

“Off with its head”. This thread covers my findings when I looked inside and also reports on my investigation into how the 1KZ-TE is designed to be cooled.

I have a few misgivings about the design which may shed light on the recurring cracked cylinder head enigma that these motors suffer. Discussion, as always, will be welcomed.

The cylinder head was removed and cleaned-up. It looked fine and I don’t think there is a problem with it. Its only done about 2,500 miles since it was fitted last June. The first thing I noticed was that one of the ‘blanking panels’ in the head gasket had been inflated. They should all be flat and the old gasket I took out when the head was replaced hadn’t suffered in this way. This was a pattern ‘three hole’ gasket from Milners – it consists of three thin metal gaskets riveted together. It appears that combustion pressure was getting in between the top and centre sheets as the bottom panel was still flat.

This is the front nearside panel, just below the top radiator hose outlet: Other panels in the gasket were normal. Looking closely at the face of the block, the gasket and the cylinder head didn’t show any obvious ‘blow-by’, though I have my suspicions about the rear nearside water channel as the block was a bit discoloured and No. 4 cylinder had a sort of ‘rusty’ look to it (it was like that when the head cracked, but I thought it would have been all shiny again by now). So, maybe I was getting combustion pressure from No. 4 into the coolant and maybe not. When I fitted the new head I didn’t use any gasket sealant on the head gasket. This time I used a genuine Toyota gasket and put a thin layer of non-setting sealant on both sides of the gasket.

I was very careful not to get any sealant near the camshaft oil feed drillings as I wouldn’t want that blocked. Time will tell if this was a better approach. So, I may have had a leaky head gasket, I don’t know for sure, but what about the way the motor is designed? Is there anything I can do to improve the cooling when towing?? There are a couple of unusual features with this engine the main one being that this is the only engine I have seen where the thermostat is on the cold water return-side from the radiator.

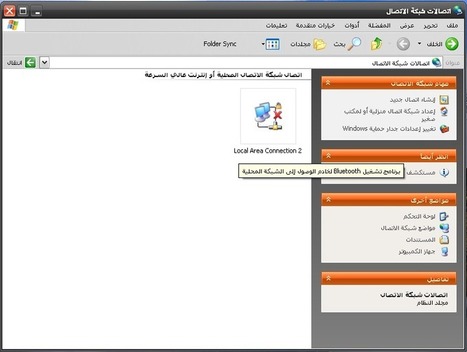

There are undoubtedly others, but I don’t really understand how they are supposed to work. I’ll explain. You may be forgiven for thinking that there is a thermostat in here – in the ‘usual place’. But there isn’t, its down here, just behind the alternator. As we know, a number of the water channels that connect the head to the block are blanked-off by the head gasket – they can be seen here – four on the nearside & one on the offside: (Note to all you people who drive on the wrong side of the road. British Standard Nearside is the left of the motor, viewed from behind from the driving position).

Also, the water pump has no external hoses – it doesn’t take its water directly from the radiator: Instead, the water circulates around the block, past the thermostat – where it is joined by the coolant being returned from the Turbo and the cabin heater and past the large drain hole from the cylinder head. Then around to the front, where the gallery emerges at the centre of the water pump. The pump then sends it around to the nearside, below the cylinder head and below the channels blanked-off by the head gasket. Now we see why the water galleries feeding the head are blanked-off, the water (presumably from the coolest part of the engine) now flows between the block and the oil filter housing where it cools (or warms-up) the oil cooler. Above the oil cooler are three 5mm holes linking the block and the head, they won’t affect the water circulation much and, I suspect, are primarily there to prevent air locks building up in the block. On my engine, the holes in the block were a bit rusted-up so I cleaned them out with a 5mm drill bit.

The head gasket also had 5mm holes but the head only had 4mm – I drilled these out to 5mm to line everything up and to reduce the risk of blockage. I don’t think the additional 1mm (x 3) will affect the coolant flow. The coolant now runs to the nearside rear of the block where it meets the first of the galleries connecting the block and the head. As the bulk of the flow continues around the back of the motor it meets more open galleries – allowing water to rise into the head. At the front off-side of the head is a large drain hole that lets the coolant drop down to the suction side of the water pump.

I am assuming at this stage that the thermostat is closed and there is therefore no flow into the radiator, apart from some thermo-syphon exchange that causes the top of the radiator to get hot. It seems a bit strange to me to deliver the water from the head – probably the hottest part of the motor – downstream of the thermostat. I have marked-up a picture of the block to illustrate my perception of the coolant flow: As well as the flow up into the head, there is a flow forward on the off side below the head. Hot water from the head is also routed to the cabin heater, returning to the block upstream of the thermostat.

This flow is presumably cooler than the water in the head, so will keep the thermostat cool. I guess this is to maximise the heat transferred to the cabin.

I’m not sure about the turbo charger. There is one feed from the bottom of the block (coolest water) and another just forward of the thermostat. I’m assuming that it’s a thermo-syphon system with the heated water rising up to the upper hose, unless someone can tell me that there’s an impeller in there between the hot and cold sides of the turbo. So far so good.

With the thermostat closed we have a water circulation around the block and the head, with the hottest part being up top, in the alloy head. And this is where I have a problem. Normal thermostats that live near the top radiator hose typically open at around 88 degrees Centigrade.

One would expect that one living on the return side would have a lower opening temperature – and it does, the standard ‘stat for this motor opens at 82 deg C: However, I carried out an experiment. I heated the standard stat up in a pan of water and it gradually opened. I ran the hot tap in the kitchen until I couldn’t put my hand in it, then transferred the open stat to the hot tap water – It shut fast in under 3 seconds. I then put the stat back into the almost boiling pan and it took a long time to open.

I repeated the swap and it shut very quickly. Now, the ‘stat lives in the block with the business end on the inside of the motor. As the motor heats up it will presumably get to the point where it opens and is immediately flooded with cold water from the bottom of the radiator.

1kz Te For Sale

It seems it will then close very quickly. Repeat the process – long(ish) time to open followed by a quick shut-off. I think its very unlikely that the bottom of the radiator will ever get to the temperature where the thermostat stays open (unless you’re stuck in traffic in the Sahara), meaning that the motor is being fed small gulps of cool water. That is probably OK if the car is running light – but towing a couple of horses over the Pentland Hills??? No wonder the motor gets hot and objects. Its working hard but there is sufficient airflow to keep the radiator cool, so the thermostat stays predominantly shut.

I can see why the motor may get so hot in places that the head is strained – and cracks. Or does the ‘stat reach a steady state where it balances the heat in the block with the cool water from the radiator? I don’t know, but I’ll bet it doesn’t open fully very often. This is not a problem where the ‘stat is at the top of the motor as, when it opens, it is bathed in hot water and so stays open until the whole motor cools down to below its opening temp. I looked on various websites and all quote the standard ‘stat for this motor as being 82 deg. However, Land Rover Defenders have 88 deg stats, with 74 deg versions as an option. The Max Ellery manual for the 1KZ-TE states that the standard ‘stat is 74 degrees!

I enquired of Toyota and a 76 deg ‘stat is available – so I’ve fitted one: Whether this will make a difference remains to be seen but my gut feeling is that it won’t. I took the truck for a run (without a trailer) and when I got home the top of the radiator was hot, but the bottom hose was stone cold. I know that to achieve thermal efficiency the combustion chamber has to be as hot as possible, but unless I’m missing something obvious this design is flawed. My temperature gauge doesn’t normally move from the normal mark – even when its chucking the coolant out. It only reads high when its lost most of the coolant from the head and top of the block and by then it could be too late. Oh yes, the radiator and cap were new last June.

I flushed it out with a hose and it is clean inside. So, the next step if I still lose coolant when towing??

– modify the top coolant outlet to take a thermostat and remove the lower one (not that simple as there has to be a steel ring with a rubber gasket around it to make the thermostat cover seal. I’ll just cut the centre out of an old ‘stat and put the outer part back in). There isn’t a great deal of space for a conventional thermostat where the coolant exits the head so I might have to be innovative with some alloy welding. I used to have a BMW K1200 motorcycle that had a cylindrical thermostat that passed enough fluid to cool a 130 BHP motor with two small radiators (and fry my knees in traffic). Maybe one of those could be adapted to fit. Food for thought. OK folks, over to you, tell me where my theories are flawed and what I have been doing wrong.

But remember. 1,000,000 cracked heads don’t lie. Great post Bob.

You have obviously given this a lot of thought. I wonder if you could fit up a temp sender in the top rad hose outlet in the boss before the diagnostic port, this would give you an idea of how hot the coolant gets exiting the head and maybe more importantly how fast it gets hot. Small temp senders are available for bikes from Trailtech and don't even have to be permanently fitted. (I have a Honda Dominator) having one or more of these fitted would give you a more detailed picture of what is happening inside the coolant circuit. I only had the temp needle move once on my 90 manual and that was solved with a new rad, never had a problem since but maybe the design of the factory sender stops the needle moving much until things are near terminal.

I know that in the freezing weather I had almost no cabin heat the output temp was very low compared to normal. There is a lot of food for thought here.

Thanks for this interesting post. Bob, as you know, I don't have a 90 any more, but I really think that you are onto something there. That is fascinating. My head cracked on the first 95 auto and it's a major flaw in an otherwise really good vehicle.

I know you shouldn't run with out a stat really, but if you did a lot of heavy towing it might be better to do with with the unit removed. I wonder how the bottom hose would feel if you ran with no stat. I always took a cold bottom hose to mean effective cooling. Maybe it just means that no hot water is circulating!

Considering a separate oil cooler too? A full length manual rad and cooler would give better heat removal. HI Bob, Interesting post, as usual. Your theories are very sound in my mind. However, one has to wonder if Toyota could and would make a fundamental error as you suggest. For every cracked head story there seems to be another one with no trouble at all.

2011 Jeep Wrangler Cylinder Head Crack

As a brand they don't balls up too often.I suspect there is something else amiss that manifests itself as an overheat and a cracked head. Maybe the cooling system is a bit on the 'weak' side and that it just takes one other thing to be slighty amiss to knock it off course. My short term suggestion would be to run the engine with no thermostat for a bit (as per Chris) and see if the water pump is up to the job.

It could be that at relatively low engine speed (ergo road speed) and high load (high heat load) that the pump just cannot deliver enough water to the areas needed. Or, as you say, you could put a small 'bleed' hole in the 'stat to allow a min flow at all times and monitor this.

Incidentally, is the pump a Toyo pump? Also, as almost suggested by others, it might be worth investing in a Toyo rad if you don't already have one. A spurious rad my have sufficiently high resistance internally to affect the pump's performance, as above. Thanks for the responses, guys.

I would really like to get to the bottom of my problem. The Radiator was new from Milners last June. It looked OK and when I flush it out with a hose the water runs through quite easily.

I wouldn't have thought it was preventing the water pump from doing its stuff as it won't be passing anything until the thermostat is open. The water pump was also replaced last year after the original started to leak.

Its not a Toyota part (I just rushed to my local MF and took what they offered). It looked identical to the one that came out - but that may not have been a Toyota one either. Here they are, side by side: I had wondered if the block had some obstruction in it - one used to hear stories of rags being left in or the original sand-casting core formers not being removed completely but I couldn't detect anything with a probe down the cooling holes. I didn't want to start removing core plugs Initially, I had decided to modify the standard thermostat. I removed the 'jiggler' and bored the hole out to 5mm to let some coolant circulate constantly. However, I fitted the 76 deg 'stat instead so I don't know what effect that might have had. I'll keep working on the problem and will report back.

I have a horse-towing job lined up for April 11th so I'll be interested to see how it performs then. Another good write up Bob I know you probably do not want to spend any more money on the l/c but i would bin the milners rad, i have had problems with 2 rads the first weeped from the brazed joint for the atf coolant pipe and the second seemed to be letting in coolant very slowly to my auto box so i have now fitted my original rad back in that was a toyota rad and no coolant loss. So I'm not very confident on the quality of the rads. I'm also interested to see if the lower temp thermo works as i have the opportunity to take my uncles twin wheeler caravan up to Scotland and would not want my l/c overheating. So if this cures/helps the problem i will be changing it.

Click to expand.Hi Cabman, I wasn't sure about the gasket but was relieved that there was no sign of etching on the head or block. If it happens again I might have to strip the motor and have the block re-faced, which would be a real pain. I now have a genuine Toyota gasket fitted and put some sealant on it in case there is a low point on the block somewhere.

Time will tell. To be fair, the Toyota gasket dodn't look at all different to the Milners one I took out - both have a sort of black paint covering.

I have a spare Milners gasket on the shelf - its a 'Tong Hong' part (or something) - never heard of it. I am not planning on using it. I have ordered a small, cylindrical, BMW thermostat and a couple of top hose outlets. I'll play around with them to see if I can get them to work. It could be an interesting experiment, I can see my lathe getting some use. Ahh, global warming you see, brought on by the greed of supermarkets.com no doubt.

When they first made them, it was cool. Now the UK has warmed up because of all the heat from the checkouts. Sorry Nick, where was it you worked? Anyway, 'ope thy ed's alreet nah. OK on a serious note, interesting that the manuals do not seem to suffer as much.

They don't share a rad with the autobox of course so get better cooling. It's not much, but I think where we are going with this is that it's only some minor changes that are needed to produce the fault. Wonder if anyone who fitted an oil cooler ever cracked a head. Better yet, who fitted a manual rad and an oil cooler. Click to expand.Hmmmm interesting. I can't believe that Toyota don't know what the problem is. Maybe we should take a different tack.

Which Toyota diesels don't suffer in this way and how are their cooling systems different to the 1KZ-TE's?? Do any other Toyota (or any other make) diesels have their thermostats on the return side, and do they suffer too??

I still think that having the 'stat on the return side doesn't feel right. I can see it being OK on a motor that runs with a steady load (generator, boat) but I can't see it reacting quickly enough to sudden increases in load.

More food for thought.

You are right, never buy chinese copy. I did that, it lasted only 4 months/6500 km!

All heads are made of aluminium. Then I bought oem Toyota head from Steve OBrien, Engine Company Services Ltd: Complete original Toyota head with Toyota head gasket (complete kit with recycled camshaft/valves, included bolts and other gaskets) was £899 about 1,5 years ago. I had to send the old camshaft and valves to them. What I have heard and understood, AMC heads are even better than original.

You can get those from Roughtrax. Click to expand.When I had my cracked head last year with the old radiator I would use up water every time the engine runs and I would see the temp gauge moving when going up hills and towing. I have had this cracked hear for nearly 3 years now. Last year I replaced the radiator and it does not use up any water when running around, only when towing and pushing it hard on the motorway.

When I replace this head, I will put a Intercooler in and maybe a second temp gauge to help monitor the temperature. So would you reccomend a chinease one or should I stick with roughtrax? Hi, I replaced mine with an AMC unit from Roughtrax.

I bought the 'ready-to-fit' option with the cam and valves fitted and shimmed. The head has been fine, but I used a pattern gasket which leaked soon after fitting. This Spring I replaced the gasket with a genuine Toyota one (and used jointing compound in case there was a low spot somewhere) and have had no trouble since.

I also replaced the radiator, water pump and put a 76deg thermostat in. Its been fine towing a double horse trailer with two large horses since then. 1kz t head gaskets leaking?? Jaronimo, I'm not sure that I understand all this.

You have an 80deg thermostat in the top and a modified thermostat in the bottom, how has the lower 'stat been modified?? On the standard set-up there is no restriction to the flow at the top and the lower 'stat is 82deg C. The problem seems to be that the top gets too hot under sudden loads and the bottom doesn't get hot enough to open the 'stat. With the lower 'stat closed, the coolant can circulate around the block. With the lower stat open the flow from the bottom of the block is stopped and coolant circulates from the bottom of the radiator, past the oil cooler (hidden behind the oil filter) around the head and out of the top to the radiator. Presumably the system relies on thermosyphon to let cool coolant replace hot coolant at the bottom of the block.

If your lower 'stat is stopping the flow from the radiator, your top 80deg C 'stat won't make any difference as it will open way before the lower one. I'd be inclined to put a 76deg C 'stat in the bottom - but I think the top stat will still be redundant - unless, of course, you have done something clever to the lower 'stat. I await an explanation with interest!